Today if that happens, if one of those suppliers goes down, all the manufacturing companies go down. “But every other company continued to manufacture cars. “Back then, something went wrong, Toyota went down,” said Barry Lynn, executive director of the Open Markets Institute, which does research on markets and monopolies. Toyota invented JIT for its manufacturing production systems in post-World War II Japan. It’s also one of the strategies professionals learn when they seek certification in Lean Six Sigma. And they got burned when some disaster hit - earthquake, terror attack, pandemic, whatever. Degradation of inventory that is stored in a warehouse for too long It’s a system any business can consider. Thing is, the quest for leanness and cost-cutting led many companies to put all their eggs in one supplier, in one country. Allon notes, I believe these developments signal. Several governments around the world are intervening in its supply chains, and Toyota and other carmakers announced they are retreating from just-in-time production (a method that minimizes inventory levels across the supply chain).

Lean is a complete system that can be used across business departments including manufacturing, production, marketing, distribution, etc. There are other ways JIT and Lean differ. “The final product goes out, and then you get a new set of inputs coming in, just as they’re needed for the next product to go out.” For the auto industry, being ready is beside the point. Just-in-time manufacturing can be practiced on its own or as one step in the lean manufacturing process.

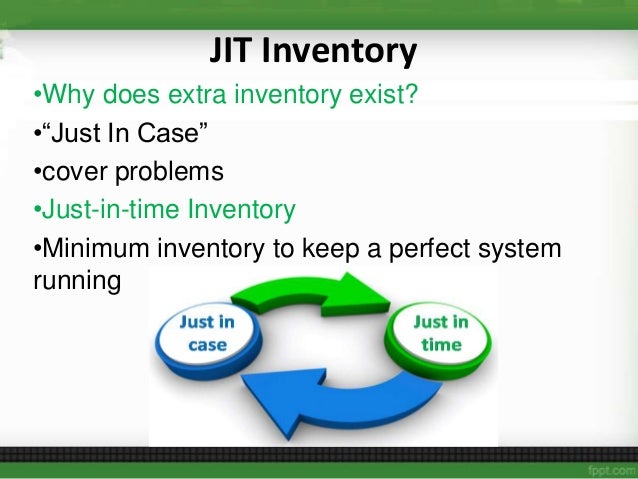

“You try to organize your delivery of them, just as you need them,” said Adam Slater, lead economist with Oxford Economics. The just-in-time model comes from Toyota, which in the ’70s started having car parts arrive at the plant at the moment of assembly. Just in Time (JIT) Inventory is a technique where in the stocks are reordered/produced only when there is an immediate requirement. And large manufacturers in Korea, including Samsung, now say their supply chain problems will stall output, too.Īt issue here is a global manufacturing model that focuses on low costs and lean inventory at every step in the chain, a model where all the parts arrive at the plant just in time.

JUST IN TIME INVENTORY LEAN MANUFACTURING SOFTWARE

Microsoft, which makes software installed in computers made in China, warned its sales will fall. The manufacturing fallout from COVID-19, the expanding coronavirus disease, continues.

0 kommentar(er)

0 kommentar(er)